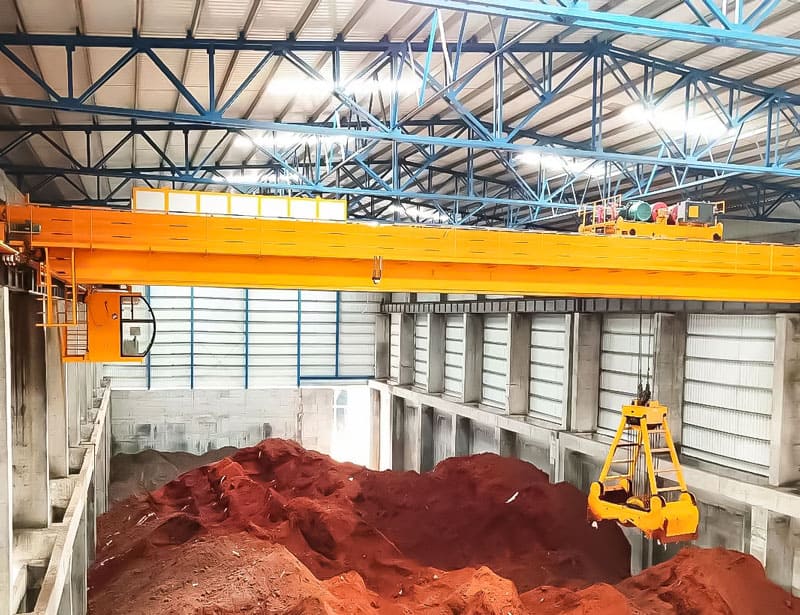

European Style Double Girder Overhead Crane

Product Details and Features

European style double girder overhead crane is a type of overhead crane that features a superior design and high-quality engineering standards. This crane is mainly used in industrial production, assembly workshops, and other industries that require a high level of lifting operations. It has several features that make it an ideal choice for heavy-duty lifting.

The crane comes with two main girders that run parallel to each other and are connected with a crossbeam. The crossbeam is supported by two end trucks that move on rails located on the top of the structure. The European style double girder overhead crane has a high lifting height and can lift heavy loads ranging from 3 to 500 tons.

One of the significant features of the European style double girder overhead crane is its robust construction. The crane is made of high-quality steel material, which can withstand high stress and load-bearing conditions. The crane also features the latest technology such as variable frequency drives, radio remote control, and safety features to ensure safe operations.

The crane has high lifting speeds, which significantly increases the efficiency of the lifting operation. It also comes with a precision micro-speed control system that allows for accurate positioning of the load. The crane is easy to operate, and it comes with an intelligent control system that monitors the crane’s performance, preventing overloading and ensuring smooth operation.

In conclusion, the European style double girder overhead crane is an excellent choice for industrial lifting operations. Its precision, ease of operation, and advanced safety features make it an ideal choice for any heavy-duty lifting requirements.

Application

A European style double girder overhead crane has become an essential tool in many industries. Here are five applications that make use of European style double girder overhead cranes:

1. Aircraft Maintenance: European style double girder overhead cranes are commonly used in aircraft maintenance hangars. They are used to lift and move aircraft engines, parts, and components. This type of crane provides a high level of precision in handling and lifting components while ensuring safety.

2. Steel and Metal Industries: The steel and metal industries require cranes that can handle extremely heavy loads. European style double girder overhead cranes can handle loads ranging from 1 tonne to 100 tonnes or more. They are ideal for lifting and transporting steel bars, plates, pipes, and other heavy metal components.

3. Automotive Industry: European style double girder overhead cranes play a critical role in the automotive industry. These cranes are used to lift and move heavy machinery and automotive components such as engines, transmissions, and chassis.

4. Construction Industry: Building construction often requires moving heavy materials to various locations on the job site. European style double girder overhead cranes provide a quick and efficient way to move construction materials like concrete slabs, steel beams, and lumber.

5. Power and Energy Industries: The power and energy industries require cranes capable of handling heavy loads, such as generators, transformers, and turbines. European style double girder overhead cranes provide the necessary strength and reliability to move large and bulky components quickly and safely.

Product Process

The European style double girder overhead crane is a heavy-duty industrial crane designed to efficiently lift and move heavy loads in factories, warehouses, and construction sites. The production process of this crane includes the following steps:

1. Design: The crane is designed according to the specific application requirements, load capacity, and material to be lifted.

2. Manufacturing of key components: The key components of the crane, such as the hoist unit, trolley, and crane bridge are manufactured using high-quality materials and advanced production techniques to ensure durability, reliability, and safety.

3. Assembly: The components are assembled together based on the design specifications. This includes the installation of the lifting mechanism, electrical components, and safety features.

4. Testing: The crane undergoes rigorous testing to ensure that it meets the required safety and performance standards. This includes load and electrical testing, as well as functional and operational testing.

5. Painting and finish: The crane is painted and finished to protect it from corrosion and weathering.

6. Packaging and shipping: The crane is carefully packaged and shipped to the customer’s site, where it will be installed and commissioned by a team of trained professionals.