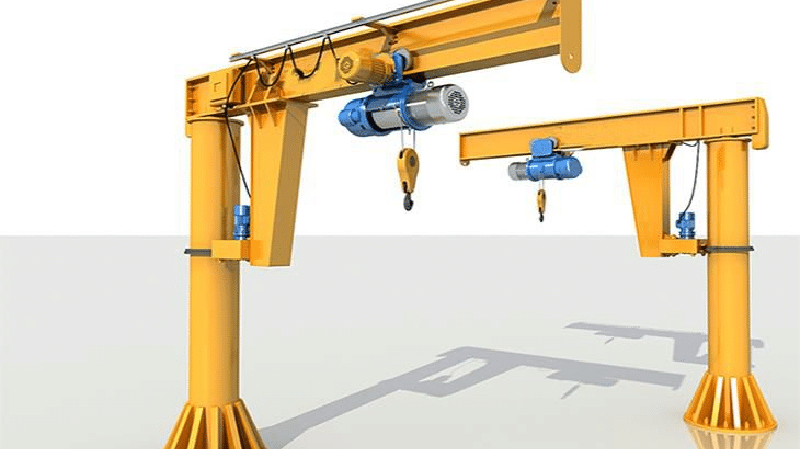

Workshop Motorized 10 Ton 16 Ton Floor Mounted Jib Crane

Product Details and Features

Floor Mounted Jib Crane will have a vertical beam, running beam, or boom, and a concrete base that. The Loading capacity of floor mounted jib crane is 0.5~16t, the lifting height is 1m~10m, arm length is 1m~10m.Working class is A3. The voltage can be reached from 110v to 440v.

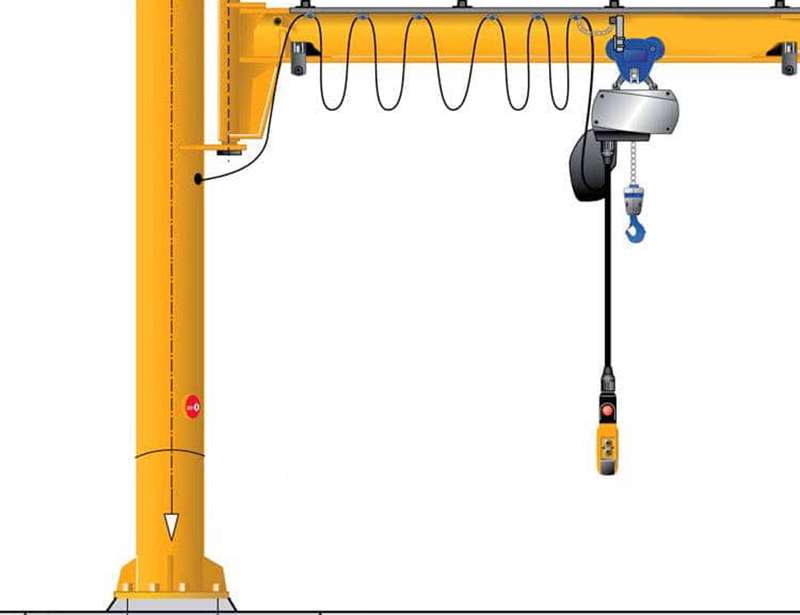

Allows the crane to sit vertically on a factory floor with no other supports. Floor Mounted Jib Crane, which are able to swing a full 360 degrees, are also light, and are made from twist-free steel-girder designs that offer a lower clearance.

Application

Floor-mounted jib cranes can be sheltered for outside use, and they are capable of fast moving items between areas of operation. Foundationless, lightweight-duty jib cranes can be bolted onto nearly any existing concrete surface, and are ideal for open areas where they can service multiple work stations. Foundationless freestanding jib cranes save installation time.

And expense by eliminating the need for foundation boring, yet they still offer full 360-degree coverage like a freestanding jib crane. Ergonomic Partners handles structural joist and floor mounted freestanding jib cranes for all of your working cage lift applications.

Just like a Floor Mounted Jib Crane, the sleeves-mounted jib crane also does not use any brackets, so you get full utilization of your entire working area around your boom. The sleeve-insert is then reinforced by a reinforced concrete foundation with the concrete being dumped second. The installers place a sleeve insert on a first pour reinforced concrete foundation first.

Product Process

Instead of the bracket, the installers place two individual foundations with the re-inforced concrete in order to stabilize them. It does not require any gussets, which allows for the complete use of working space around the boom.

Floor-mounted workstation Jib crane enclosed rail crane design keeps the roller surfaces of the carts clear, contributing to ease of operation and longer operational lifetime. It can be mounted close to walls, machinery, and other obstacles, or underneath larger overhead cranes for coverage of stages. For open-air applications, the cranes may be covered with a greater

paint coat or with a hot-dip galvanisation.It can provides 360-degree spin in tapered roller bearings that allow for a full load of vertical and radial thrust.