Heavy Duty 5~500 Ton Open Winch Trolley For Gantry Crane

Product Details and Features

The electric double-girder crane trolley is a new generation product with superior performance, compact structure, light weight, safe, reliable and efficient operation, and can meet various working conditions. Choosing a double-girder crane trolley can improve production efficiency, reduce routine maintenance, save energy consumption, and achieve a better return on investment.

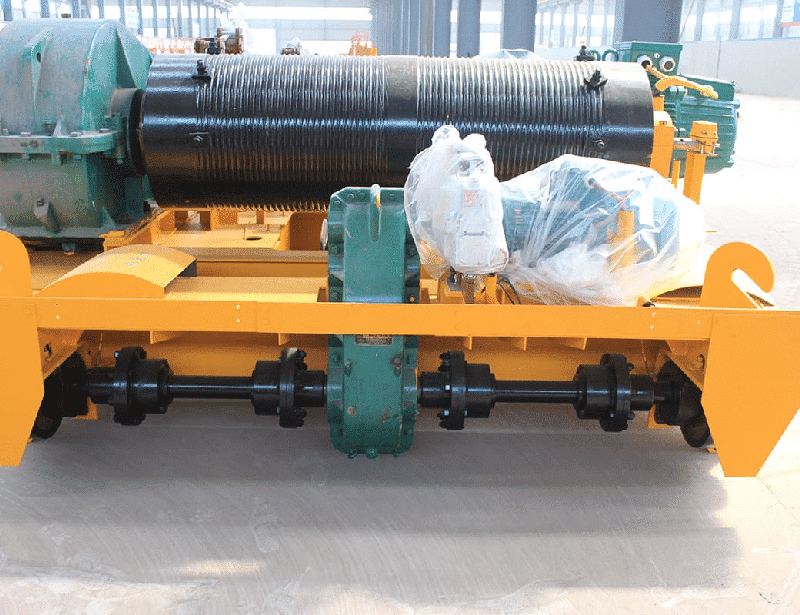

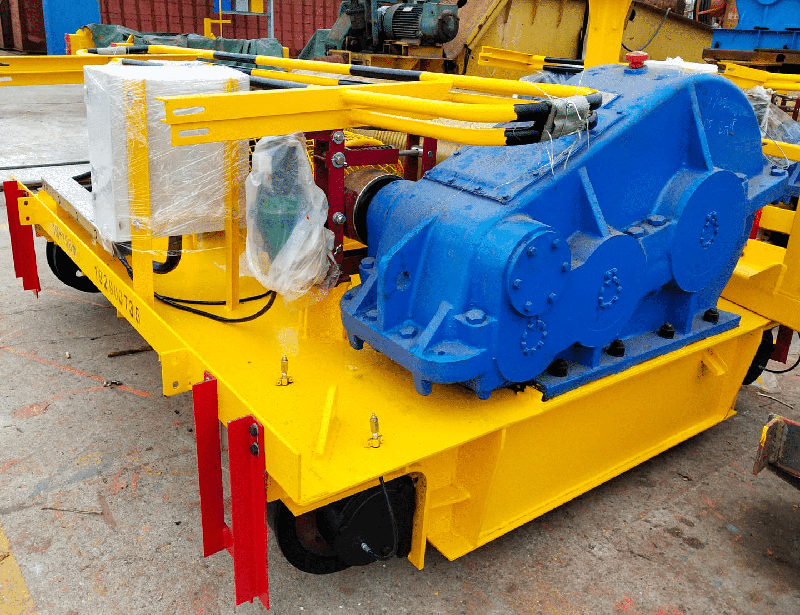

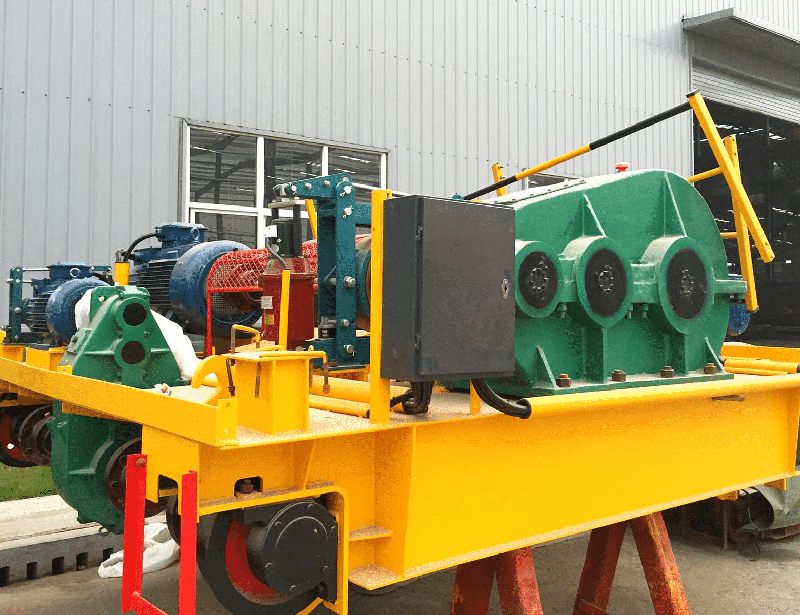

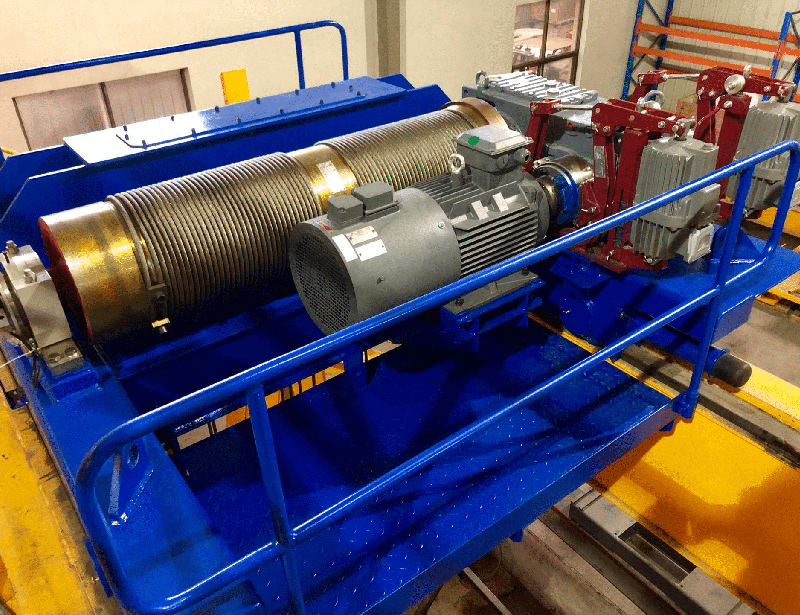

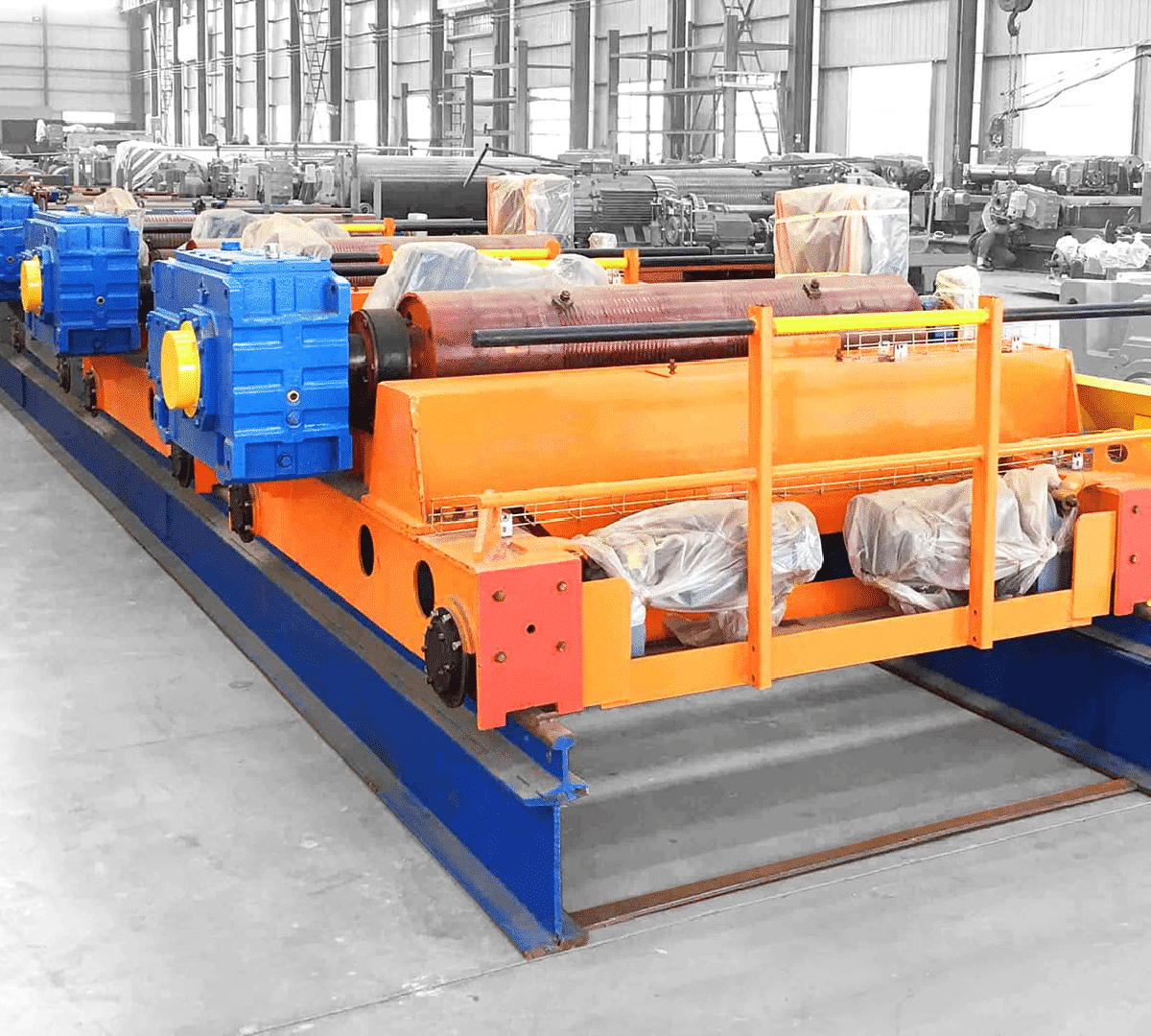

The electric double-girder crane trolley is composed of wire rope hoist, motor and trolley frame.

The electric double-girder crane trolley is a customized product. It is generally used in conjunction with a double-girder overhead crane or a double-girder gantry crane. It can also be customized according to the environment of use to meet the needs of users .

The double-beam hoist trolley produced by SEVENCRANE can be operated by ground operation, remote control or driver’s cab, which greatly improves the work efficiency of the workshop.

Application

The maximum lifting capacity of the electric double-girder crane trolley can reach 50 tons, and the working level is A4-A5. It is advanced in technology, safe and reliable, easy to maintain, and green and energy-saving.

It is suitable for civil construction and installation projects in construction companies, mining areas and factories. It can also be used in Warehousing and logistics, precision machining, metal manufacturing, wind power, automobile manufacturing, rail transit, construction machinery, etc.

Product Process

The electric double-girder crane trolley is made of high-strength alloy steel, with light weight, stable structure and high safety. The steel structure is connected by welding or high-strength bolts, which is not only firm and reliable, but also easy to install and the installation time is short.

After the trolley is manufactured in the workshop, it needs to go through a strict test run inspection before it can leave the factory. The trolley is packaged in a non-fumigated wooden box, which minimizes bumps during transportation and ensures product quality is up to standard. Therefore, after the whole vehicle is transported, it can be directly installed on the bridge frame after a little adjustment to eliminate the transport deformation.