Explosion-Proof Electric Hoist Rail Mounted Gantry Crane

Product Details and Features

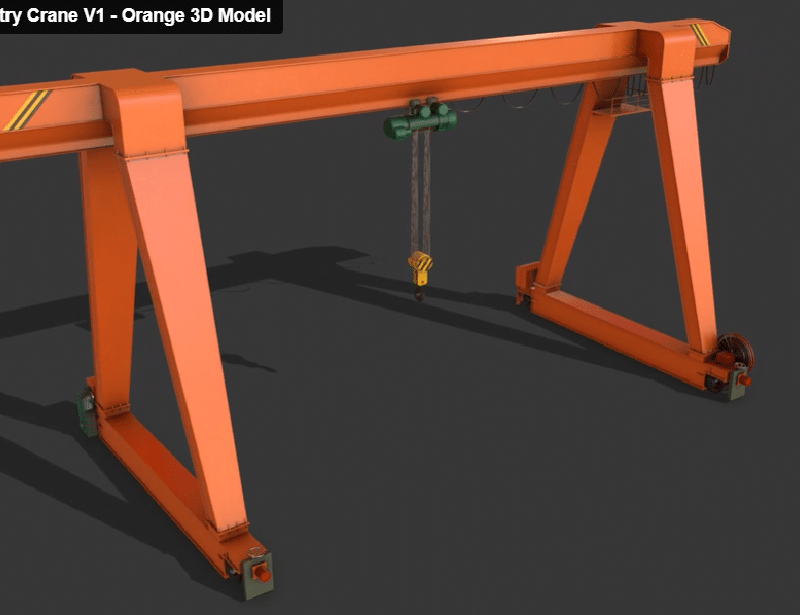

Rail-mounted gantry cranes are available in different capacities and sizes to handle varying container capacities, with their span determined by the rows of containers that must traverse. The price of a rail mounted gantry crane is highly dependent on many factors, like its lift height, span length, load carrying capacity, etc. Each factor may have a strong impact on its price.

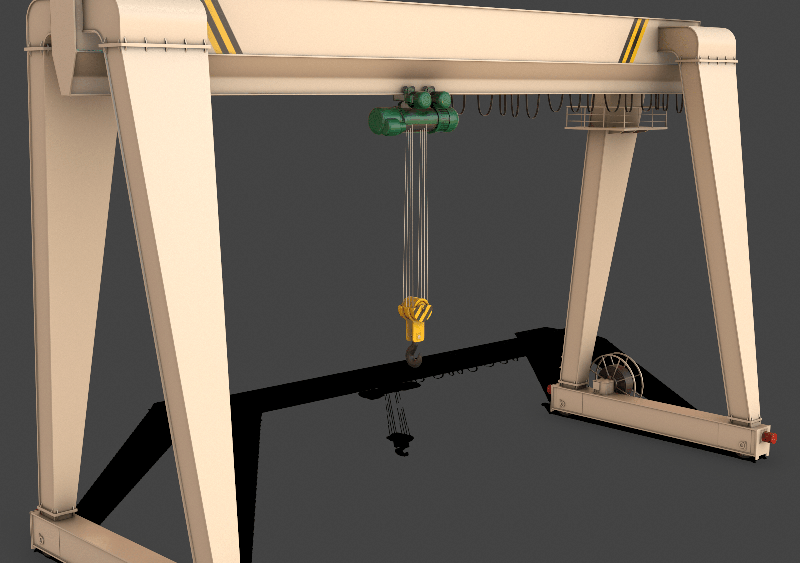

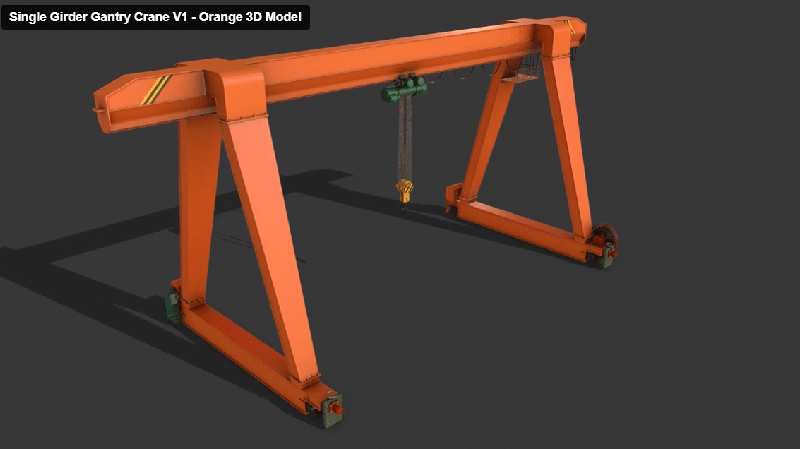

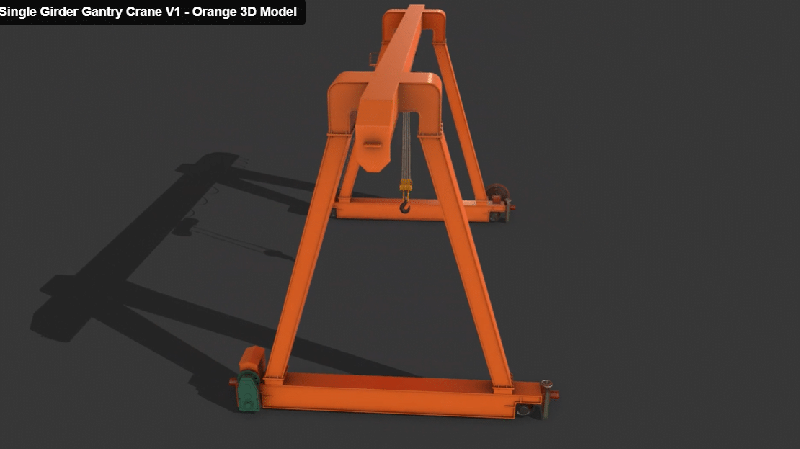

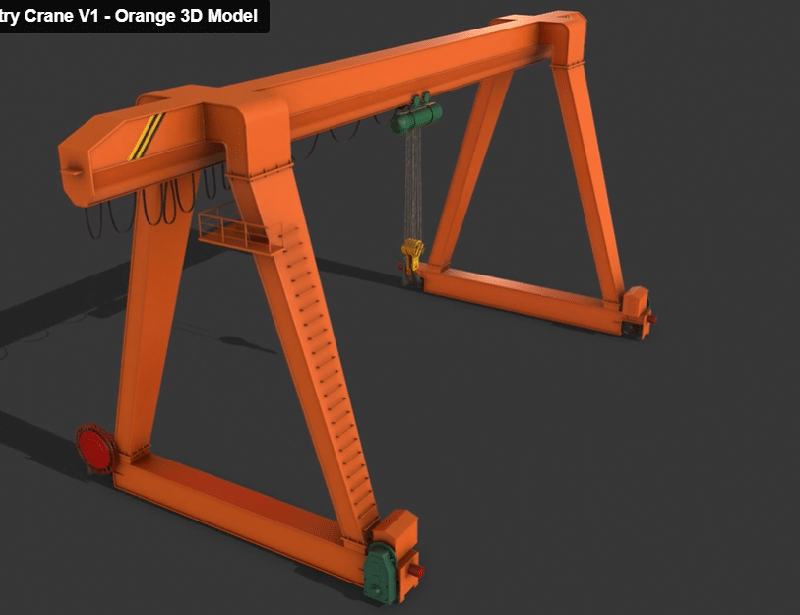

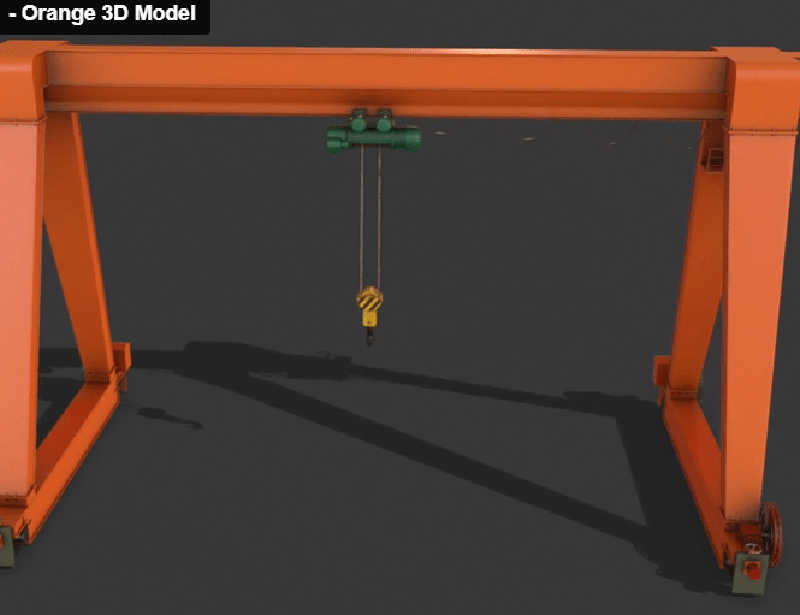

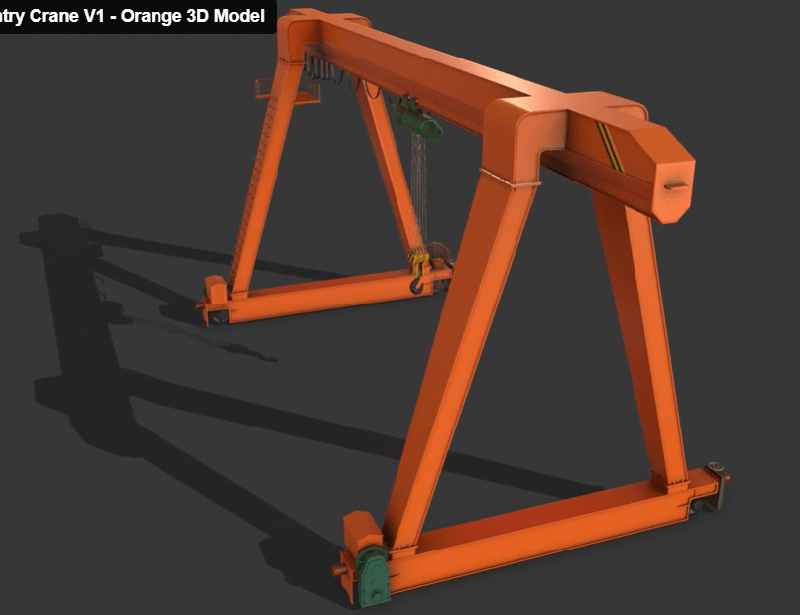

A gantry crane can be designed and manufactured according to your specific needs with different heights of piles and spans. Rail-mounted gantry cranes (RMG cranes) are particularly used to handle containers or other materials at ports, yards, piers, piers, warehouses, workshops, garages, etc. We can design them as either single-girder gantry or double-girder cranes. Rail mounted container gantry crane (also called RMG crane) is a kind of big gantry crane at dockside that is found at container terminals to load and unload intermodal containers from container ships.

The entire working capacity is of Class A6. We are capable to design and build custom-built Rail Mounted Container Gantry Cranes according to your requirements. With years of experience in lifting machinery design and manufacturing, we provide an extensive line of cranes that fit various job sites and job requirements, including aerial, gantry, head-mounted, and electrically operated cranes. We will provide you a high-efficiency, high-reliability crane for your company. By employing our Rail-mounted Cranes, you will be able to improve your terminals capability, while maintaining high reliability, longevity, and constant operation.

Application

Rail mounted cranes are generally used to load and unload containers at ports and piers, and have features such as fast operation speeds and leveling. The container crane is designed with remote and automated controls, ensuring safer and efficient operations. If a user requests a reduction in the operation intensity and an increase in the performance, a stabilizer can be provided for the crane. The crane provides high productivity, reliability, lower operation costs, and lower power usage, playing a critical role in making the stacking operations of yards easier.

Product Process

The cranes gantry has excellent performance and steady motion, with no swinging in the operation of the crane. The RMG has a high operating speed and a high working level, which allows for an extremely smooth operation, which speeds the turnover rate of the container handlers or other cranes. The RMG crane, used to load and unload different types of containers, may be the basic piece of equipment that you notice in most yards. Zhonggong provides professional railway-mounted gantry cranes for sale, Our RMG cranes combine decades of crane design experience, to deliver higher productivity, higher reliability, and operating precision, and at the same time, greatly lower operation costs and power usage.

Wolfers portfolio includes a broad array of driving solutions, which are necessary to efficiently operate a container crane system. The Crane Systems Group at TMEIC has the technical know-how and the know-how to assist ports in meeting and exceeding their goals. Each crane style is designed and built to specifically fit the needs of your operation. For instance, the operation with a partial load (S3) or frequency converter operation (S9) are considered in the optimization of Wolfer RMG crane engines.