Stereoscopic Warehouse Automatic Intelligent Crane

Product Details and Features

A logistics operations planning knowledge-based system to mitigate risks of warehousing fulfillment. Design and implementation of Internet-of-Things-based warehouse management systems for intelligent logistics. New stereoscopic Warehouse Automatic Intelligent Crane use real-time scheduling for pick-up in a warehouse.

Bi-directional racking with automated pick-and-drop system for consolidated warehouses. A two-command-cycle dynamic sequence approach for considering greenhouse gas efficacy of multi-rack automated unit-load storage and retrieval systems. Power-loading control improves the energy-dependent costs of multi-lane automated storage and retrieval systems with mini-loads.

Stereoscopic Warehouse Automatic Intelligent Crane can not only increase efficiency, they also decrease the harm to goods. This system can shield the surfaces of the goods against the damages in a greater degree during operation.

The automated stereo warehouse is also incredibly easy to work with, and it can dramatically increase utilization rates in the space in storage. With a combination of automated warehouse equipment and a computerized management system, STRONG TECHNOLOGY has developed an automated stereoscopic warehouse on its own, which is capable of high-level streamlined, automated entry, and operational simplicity in the stereoscopic warehouse.

Application

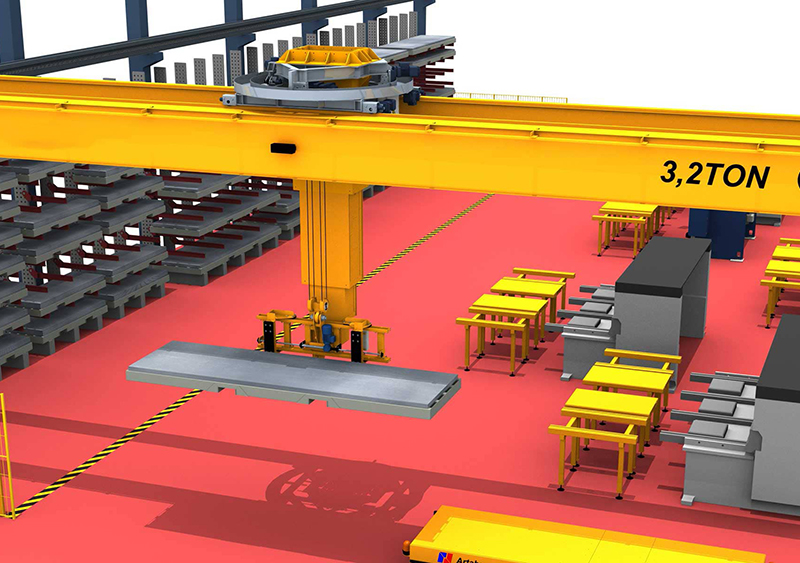

The Intelligent Stereoscopic Warehouse is composed of shelves, road-type racking (stacking) cranes, warehouse in-store (out-of-store) working platforms, a distribution control system, and management systems. The basic structure of an automated stereoscopic warehouse is composed of shelves, Stereoscopic Warehouse Automatic Intelligent Crane, an in (out) warehouse working platform, and an automated transfer (egress) and operations control system. Automated warehousing systems can be divided in three layers, with a higher level being a Warehouse Management System, which is responsible for processing warehouse enterprise logic, and the lower layers being the logistics-specific hardware, like roadway stackers, AGV systems, etc.

Product Process

It is responsible for moving goods, or picking up goods from a stacker. WCS systems are warehouse management systems in logistics, its full name is Warehouse Management Control System.

For the reduction in labor intensity in distribution, as well as saving warehouse space, Stereoscopic Warehouse Automatic Intelligent Crane systems came to existence, which became a key piece of hardware for smart warehousing. As far as warehouses using pallets are

concerned, the best of extraction and storing can be automated at different levels through Pallet Shuttle systems and Stacker Cranes (AS/RS for pallets).

The different companies comprising a supply chain must gradually adopt technologies like Stereoscopic Warehouse Automatic Intelligent Crane and a WMS in order to reach an agile and flexible supply chain able to adjust to the logistics complexity nowadays. For that reason,software — specifically, a Warehouse Management System — is critical in making sure the operators at a facility are performing their tasks effectively and rapidly.