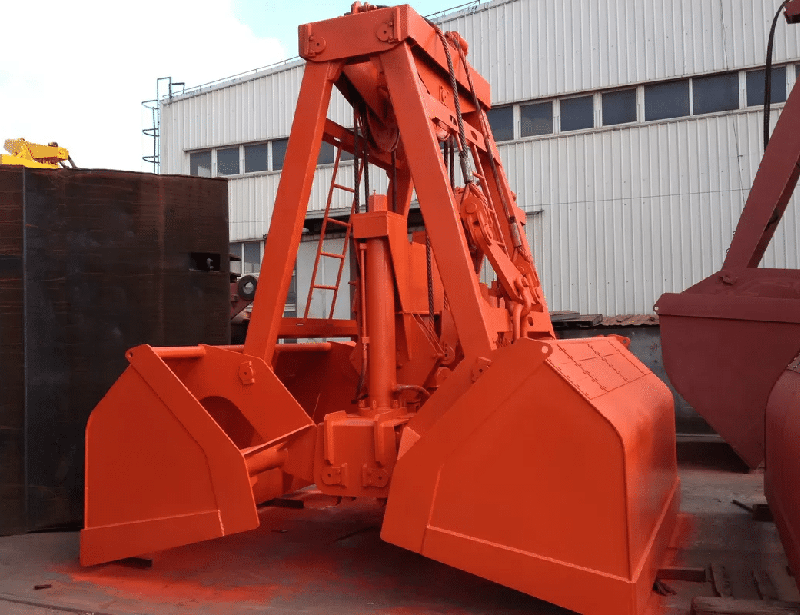

Orange Peel Clamshell Hydraulic Timber Log Waste Scrap Grab Bucket

Product Details and Features

Grab bucket is a special tool for cranes to grab dry bulk cargo. The container space is composed of two or more openable and closable bucket-shaped jaws. When loading, the jaws are closed in the material pile, and the material is caught into the container space. When unloading, the jaws are in the material pile. It is opened under the suspended state, and the material is scattered on the material pile. The opening and closing of the jaw plate is generally controlled by the wire rope of the hoisting mechanism of the crane.Grab bucket operation does not require heavy manual labor, which can achieve high loading and unloading efficiency and ensure safety. It is the main dry bulk cargo handling tool in ports. According to the types of working goods, it can be divided into ore grabs, coal grabs, grain grabs, timber grabs, etc.

Application

The grab can be divided into two categories according to the driving method: hydraulic grab and mechanical grab. The hydraulic grab itself is equipped with an opening and closing structure, and is generally driven by a hydraulic cylinder. The hydraulic grab composed of multiple jaw plates is also It’s called a hydraulic claw. Hydraulic grab buckets are widely used in hydraulic special equipment, such as hydraulic excavators, hydraulic lifting towers, etc. The mechanical grab itself is not equipped with an opening and closing structure, and is usually driven by a rope or connecting rod external force. According to the operating characteristics, it can be divided into a double-rope grab and a single-rope grab.

Product Process

The common failure in the use of grab buckets is abrasive wear. According to the analysis of relevant data, it can be found that among the failure modes of grab buckets, about 40% of the failure modes are lost due to pin wear, and about 40% are lost due to wear of bucket edges. About 30%, and about 30% of the loss of work performance due to pulley wear and other parts damage. It can be seen that improving the wear resistance of the pin shaft and the bushing of the grab bucket and improving the wear resistance of the bucket edge are important ways to improve the service life of the grab bucket. In order to improve the service life of the grab bucket, our company selects different wear-resistant materials according to the different conditions of each wear part of the grab bucket, and supplements it with different processing techniques, thereby greatly improving the service life of the grab bucket.